Redefining Injection Molding

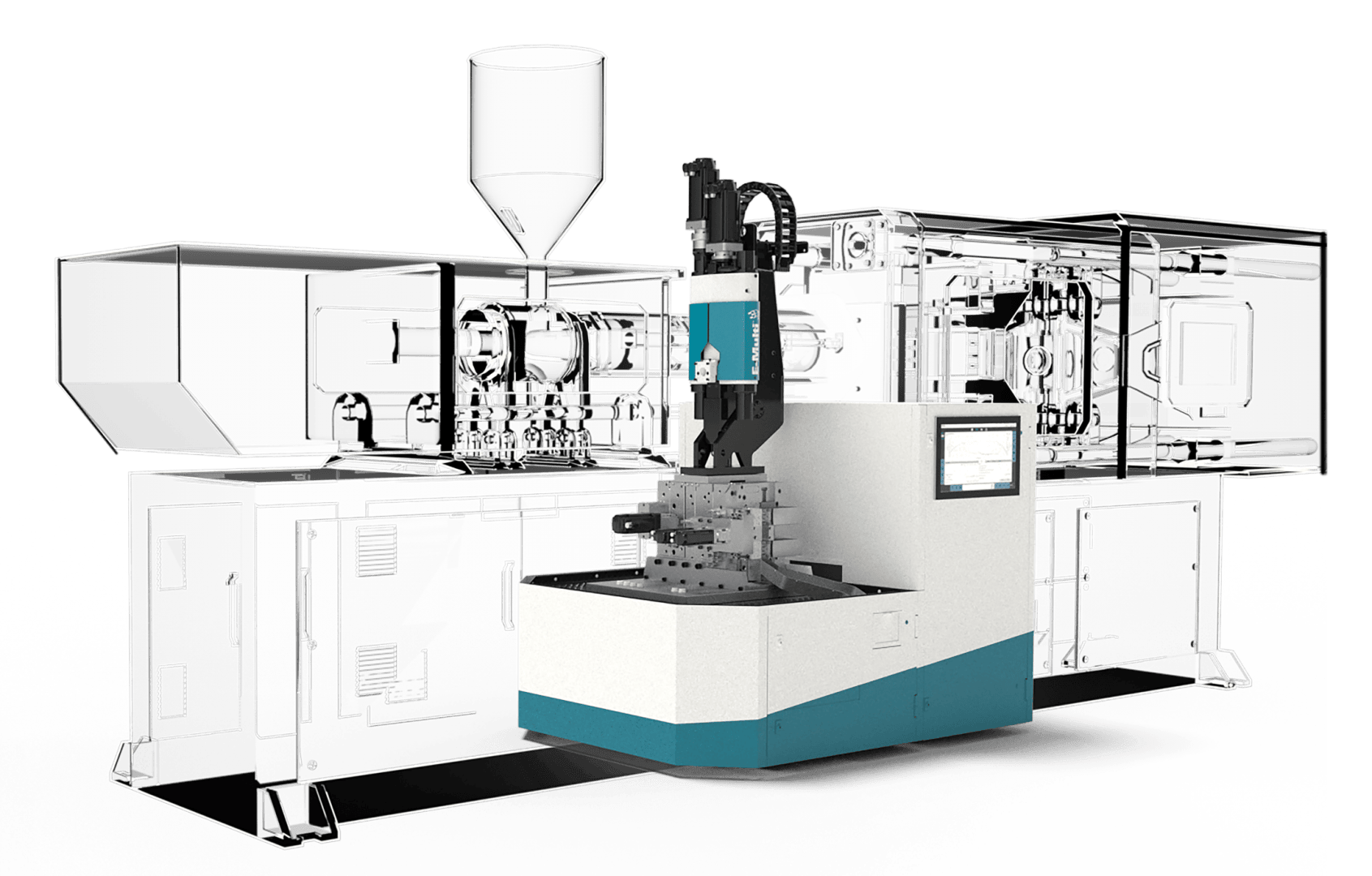

Our compact, turnkey injection cell eliminates the need for conventional injection molding machines. Optimized for small part production, it enhances molded part quality while offering increased productivity. Ideal for the high-volume production of light weight medical components..

Rethinking the Process

With our groundbreaking Incognito Production Technology, traditional injection molding is being completely reimagined. The clamping unit is fully integrated into the mold, making a separate machine unnecessary.

The result: superior part quality, significantly shorter cycle times, and a compact system that redefines efficiency.

In short — better parts, lower costs, smarter production.

Intelligent Process Control

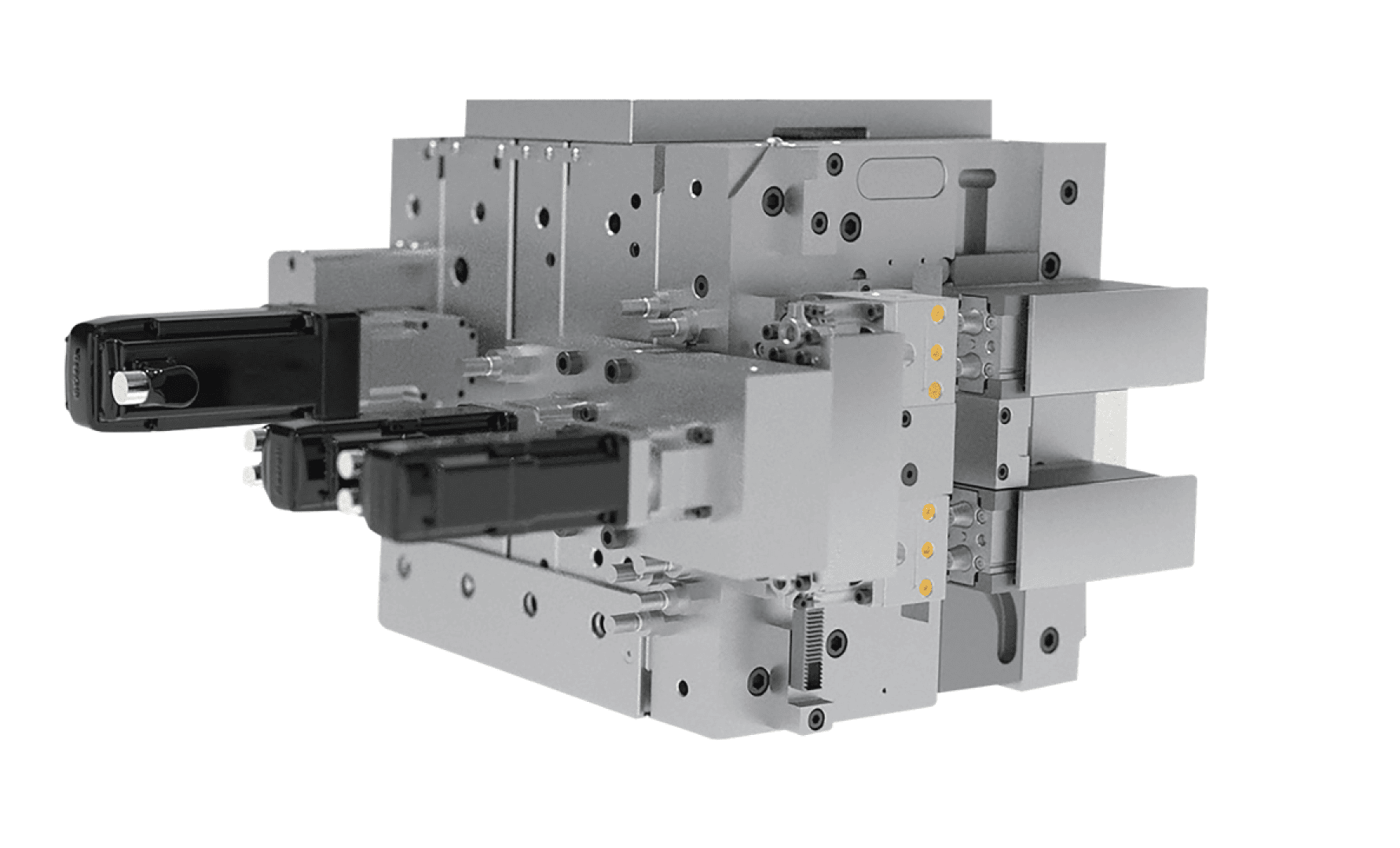

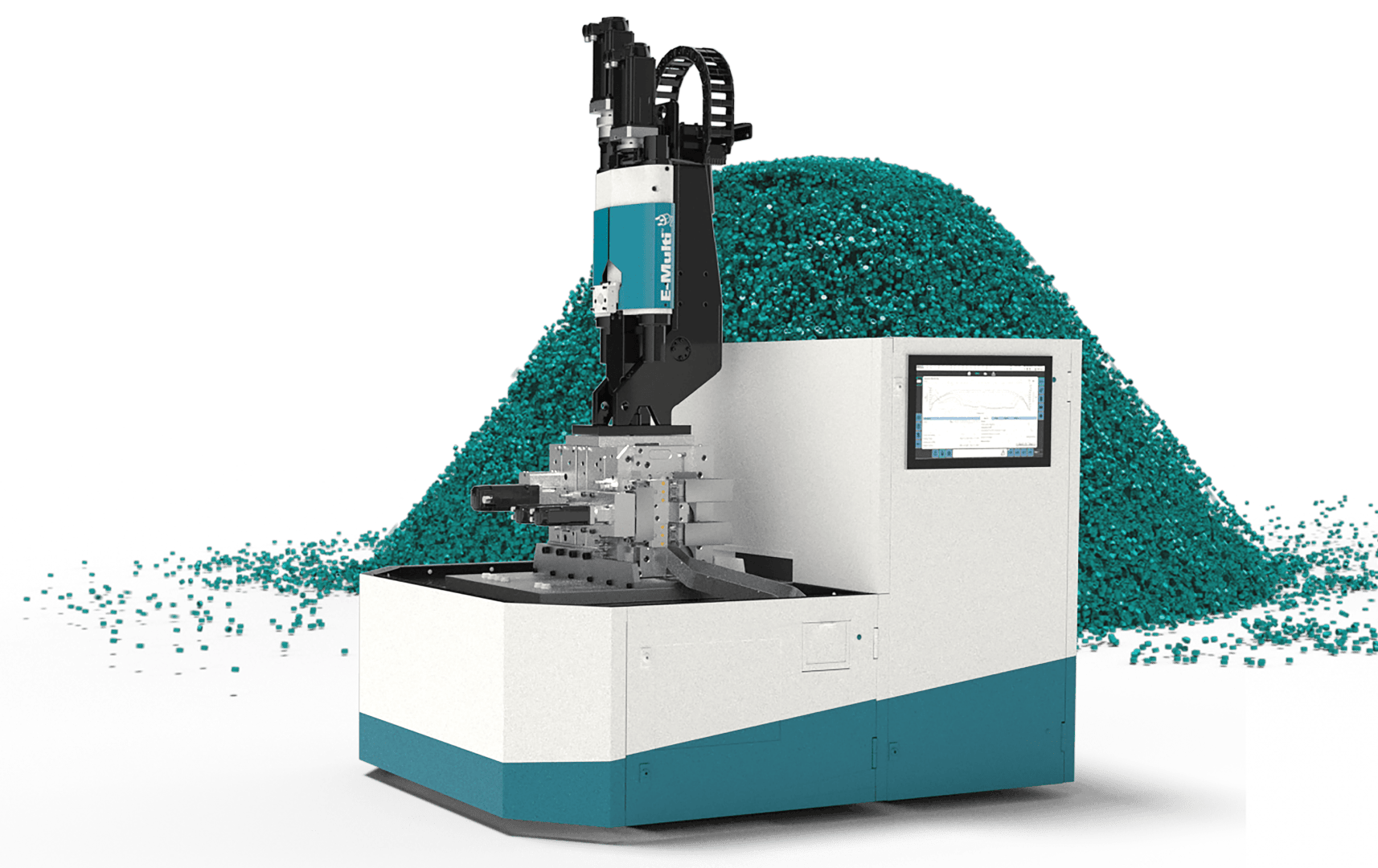

Incognito Production Cell is a fully electric, plug-and-play solution that combines the injection unit, hot-runner system with NV nozzles, and advanced process control modules — all driven by precision servomotors.

Unlike hydraulic or pneumatic systems, servos are cleanroom-compatible, energy-efficient, and maintenance-friendly. Our unique closed-system design minimizes injection and clamping forces. Once the system is closed, actuators simply hold position without applying force — drastically reducing wear and enhancing part quality.

Less stress. Less maintenance. More precision.

Productivity — Elevated

Smaller movements, lighter components, faster cycles. Our technology cuts cycle times by up to 25%, while eliminating cold runners can reduce material consumption by as much as 75%. The modular cavity design scales effortlessly up to 96 cavities, ensuring maximum flexibility and productivity.

More output. Less waste. Greater value.

Compact Size

The cell is compactly designed and no longer requires a clamping mechanism. Plastic components can be produced in an extremely small footprint — with minimal energy consumption and whisper-quiet operation.

With production areas reduced by up to 80%, you save not only energy but also valuable floor space.

Compact production has never been this efficient.

Easy Maintenance — Low Risk

Smart design means simple service. The Incognito System is fully modular — with interchangeable units such as slides, high-pressure modules, and thread cores. Just a few screws are all it takes to replace parts.

A 96-cavity mold consists of 48 modular 2-cavity units — minimizing downtime and ensuring smooth, continuous operation.

Fast Delivery — One Partner

Everything from a single source. One contact. One order. This streamlined approach shortens your time to market (TTM) and simplifies project management. On request, we deliver your system fully tested, including Site Acceptance Test (SAT).

The advantages speak for themselves:

- Premium part quality

- Intelligent process control

- Up to 25% faster cycle times

- Up to 75% material savings

- Up to 80% smaller footprint

- Lower energy consumption

- Minimal maintenance and downtime

Need higher output? Simply combine multiple cells, integrate them into an assembly line, or add separation, packaging, and inspection modules.